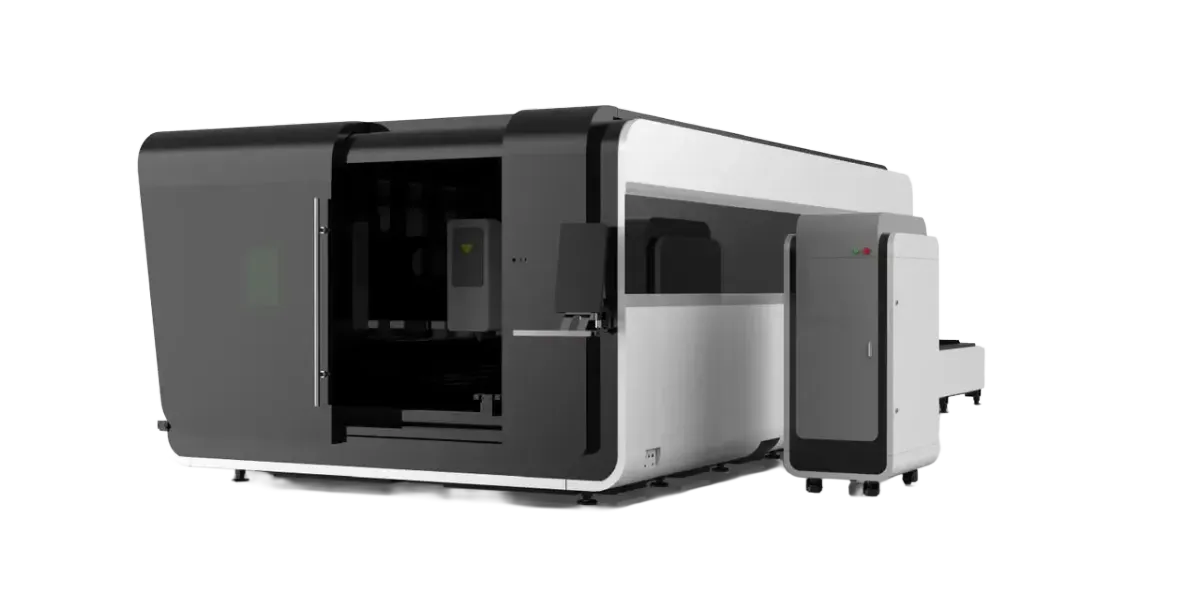

Precision Laser Cutting for Industrial Grade Parts

High-accuracy cutting, clean edges, and fast turnaround for prototypes and production runs.

Our 12kW fiber laser delivers tight tolerances, clean cuts, and consistent performance across carbon steel, stainless steel, and aluminum. Whether you need a single prototype or a full production run, we cut each part with the speed, precision, and reliability your workflow demands.

What Our Laser Can Handle

Maximum Cutting Thickness

Up to 1.5 inches, depending on Material

Cutting Area

13' x 6.5' cutting envelope

Material Compatibility

Carbon Steel (Mild Steel)

Stainless Steel

Aluminum

Brass

Copper

Galvanized Steel

Performance & Quality Advantages

High-speed cutting for thick-gauge materials

Tight, repeatable tolerances

Virtually dross-free edges

Narrow kerf for precision work

Large-format cutting for oversized parts

Exchange-table efficiency for higher throughput

Pre-Weld Laser Cleaning: Integrated laser cleaning removes rust, paint, and oxides to ensure a perfect surface for downstream welding

Why Choose Belka For Laser Cutting

High-Power Cutting for Thick Material

Our 12kW fiber laser delivers exceptional performance on thick-gauge metals, making it ideal for both heavy-duty parts and high-volume production.

Clean, Accurate Edges

We produce tight tolerances, narrow kerfs, and virtually dross-free edges — ready for welding, finishing, or direct assembly.

Built for Speed & Efficiency

Our exchange-table system allows fast material loading and unloading, reducing downtime and speeding up your job without sacrificing quality.

Large Format Capacity

With a 13' x 6.5' cutting envelope, we handle oversized parts, longer components, and nested batches that other shops may struggle with.

One Shop for the Full Workflow

Move seamlessly from cutting to forming, laser welding, and final assembly. We eliminate lead-time delays and reduce multi-shop coordination issues by handling the entire fabrication process in-house.

Fast, Responsive Communication

You won’t wait days for a response. We review your files, provide feedback, and deliver quotes quickly so you can keep production moving.

Applications We Cut Every Day

Common Application Types

Brackets and Plates

Structural Components

Machine Parts

Mounting Tabs

Industrial Covers and Panels

L-brackets and gussets

Equipment components

Industries We Serve

General Manufacturing

Industrial Equipment Builders

Automotive & Off-Road

Agricultural Equipment

Construction and Fabrication Shops

Contractor Supply

Machine Shops needing overflow cutting

Perfect For:

Prototype runs

Small to medium batch production

Replacement parts

Custom one-off components

High-volume nested cutting

Materials and Thickness Guide

Materials We Cut

Carbon Steel (Mild Steel)

Stainless Steel

Aluminum

Galvanized Steel

Brass

Copper

Cutting Thickness & Area

Up to 1.5 inches thick, depending on material

13' x 6.5' cutting envelope

A Simple Process to Get Your Parts Cut Fast

Step 1 - Send Your Project Details

Provide your idea, files, sketches, or describe the part. We'll review it quickly.

Step 2 - Get a Fast Quote

Clear pricing and lead times with no surprises.

Step 3 - Receive Precision-Cut Parts

Your parts are cut accurately and delivered on schedule.

Precision Laser Cutting, forming, and welding.

© 2026 Belka Laser and Fabrication | All Rights Reserved

Privacy Policy | Terms of Service | Disclaimer

Website by Thornapple Tech